Polyamis

Polyamis compounds are engineered polyamide solutions based on PA6 and PA6.6, with or without glass fiber reinforcement. Designed for Automotive, Industrial and Consumer Goods applications, they offer excellent mechanical strength, thermal resistance and dimensional stability. Recycled-content options are available to support more sustainable manufacturing.

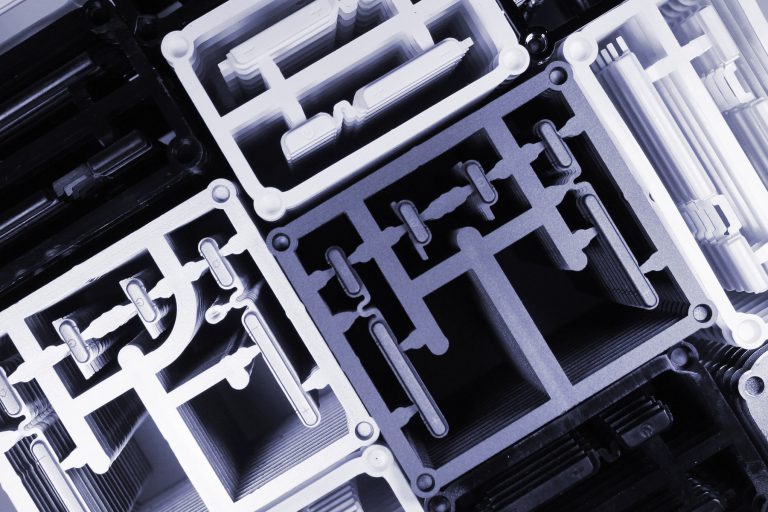

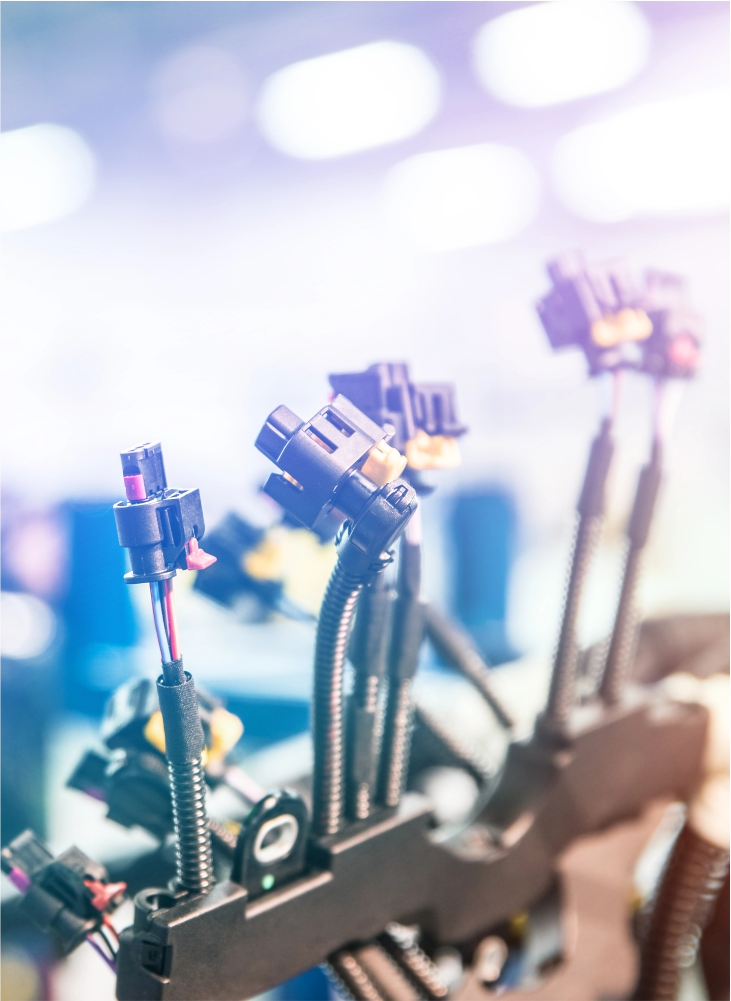

Automotive Injection & Extrusion Moulding

Polyamis compounds based on PA6 and PA66 are tailored for automotive injection and extrusion moulding, supporting interior, exterior, and under-the-hood applications. Their high mechanical strength, heat resistance, and dimensional stability make them ideal for demanding structural parts, EV plug handle cores, and engine compartment components. Glass-fiber reinforced grades and recycled-content alternatives meet rigorous performance requirements while promoting sustainability across modern automotive design.

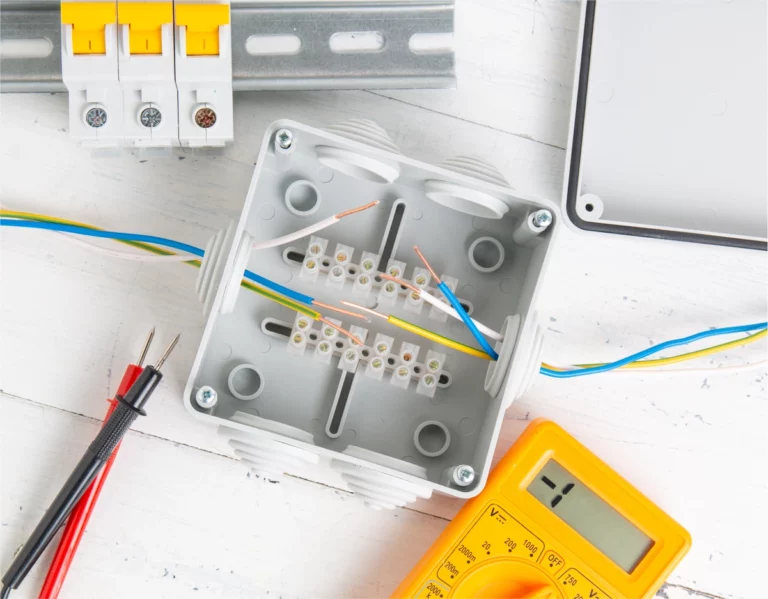

Industry Injection & Extrusion Moulding

For industrial components requiring high durability and resistance, Polyamis PA6 and PA66 compounds offer robust performance in injection and extrusion processes. Ideal for electric housings, fuse boxes, building components, and railway parts, these materials provide excellent thermal stability, strength, and precision. Available in glass-fiber reinforced versions and with recycled-content options, they ensure long-term reliability even under mechanical and environmental stress.

Consumer Goods & Personal Care Injection & Extrusion Moulding

Polyamis PA6 and PA66 solutions bring strength, rigidity, and high heat resistance to consumer goods and personal care moulding. From kitchenware and household appliances to sporting goods and shopping carts, these compounds ensure performance, safety, and visual quality. Reinforced grades provide structural integrity, while recycled-content alternatives help brands align with sustainability goals without compromising function or design.