Automotive

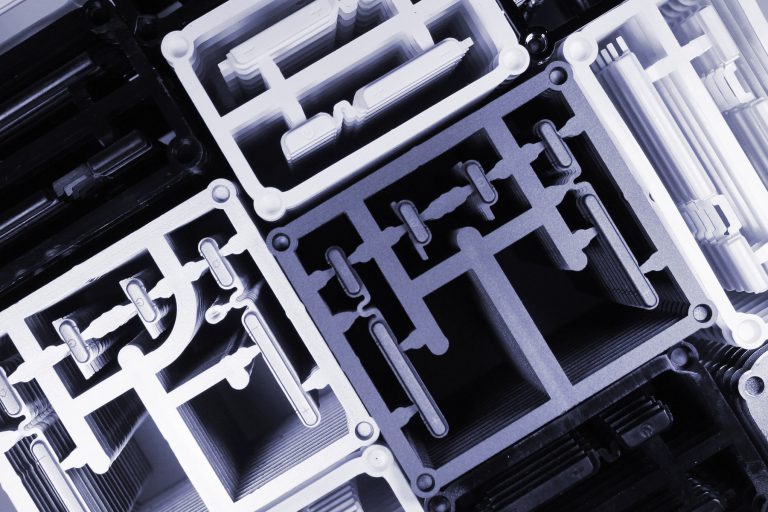

Interior Automotive TPE-S | PA6 | PP

For interior automotive components, Lacoflex® TPE-S compounds deliver flexibility and impact resistance for car mats, inlay mats, cup holders, and seat profiles, suitable for both injection and extrusion processes with recycled-content options.

Polyamis PA6 engineering plastics provide mechanical strength for structural parts, door and seat handles, and pedal structures.

Sofiprime® PP thermoplastics ensure dimensional stability for cockpit structural parts, central consoles, and interior trims, supporting efficient production and high-quality automotive interiors.

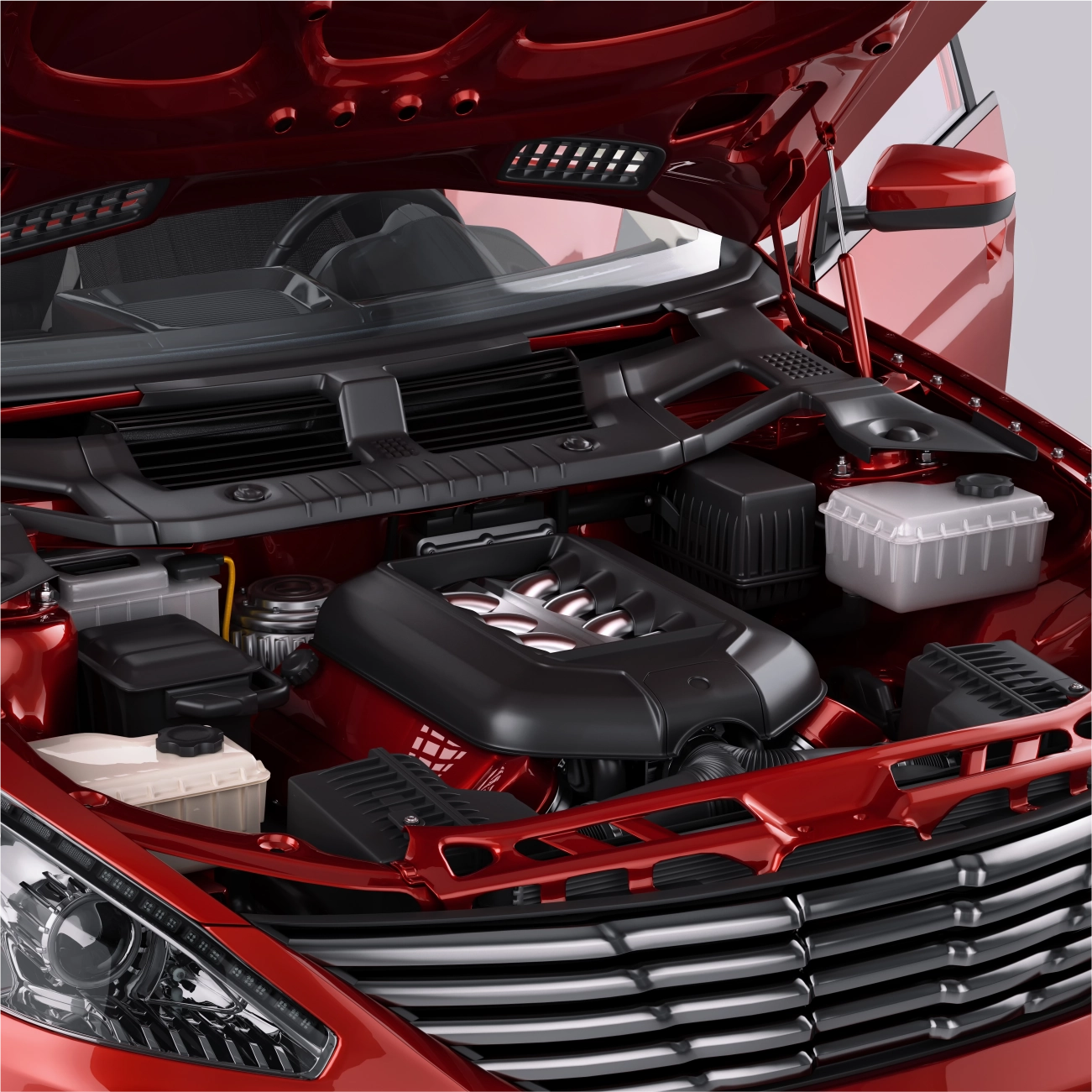

Exterior Automotive TPE-S | PA66 | PP

For exterior automotive components, Lacoflex® TPE-S compounds provide flexibility, impact resistance, and recycled-content options for glass encapsulation, mud flaps, and EV plug handles.

Polyamis PA66 engineering plastics deliver mechanical strength for EV plug handle cores.

Sofiprime® PP thermoplastics ensure dimensional stability and thermal resistance for front-end structures, underbodies, HVAC systems, and head and rear lighting housings, supporting efficient production and durable automotive exteriors.

Under the Hood Automotive

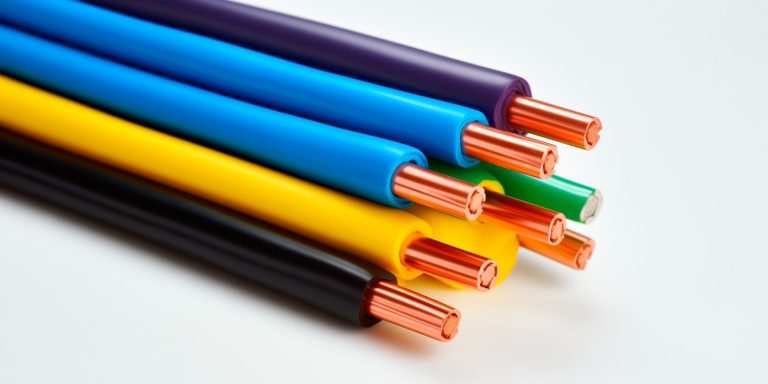

TPE-S | TPU | PA6 | PA6.6 | PP

For under-the-hood automotive applications, Lacoflex® TPE-S/TPU compounds provide flexibility and chemical resistance for wire guides, air duct sealing, and steering bellows, with recycled-content options.

Polyamis PA6/PA6.6 engineering plastics deliver mechanical strength and thermal stability for air filter structures, air ducts, fuel and washing lines, and electronics supports.

Sofiprime® PP thermoplastics ensure dimensional control and durability for engine covers and wire guides, supporting reliable performance in demanding automotive environments.